I. Introduction

Buried polyethylene (PE) double-wall corrugated pipe, is polyethylene (PE) resin as the main raw material, adding necessary to improve the performance of additives, plastics extrusion. The wall section is a double layer structure, the inner wall is smooth, the outer wall of a pipe with equally spaced trapezoidal or arcuate hollow structure. Its special structure, attractive appearance, good ring stiffness, diameter, and has good flexibility and low temperature impact performance, flexible interface with flexible rubber ring, connecting reliable, easy to leakage, moving

Convenient transportation construction, large diameter buried plastic drainage outfall preferred varieties.

Second, the application field

1, municipal engineering rainwater, sewage;

2, ventilation, drainage works;

3, industrial wastewater, residential emissions project;

4, agricultural irrigation and drainage;

5, communication cable sheathing, electrical cable sheathing;

6. Project borehole drilling pipe (perforated wall bellows);

7. Salt Brine, water fisheries;

8, hydraulic engineering;

Third, the product characteristics

1, the special structure, attractive appearance, energy efficient, low cost of project;

2, light weight, convenient loading and unloading;

3, convenient and quick construction, saving construction costs, reliable connection, easy to leak;

4, ring stiffness, excellent resistance to external pressure performance. Good low temperature resistance, impact resistance;

5, good to bypass resistance, uneven settlement performance, can be used in soft soil foundation of quicksand;

6, wall smooth, fluid resistance, no scaling, wear, through water and strong;

7, corrosion-resistant, non-toxic, non-polluting, environmentally friendly, long service life.

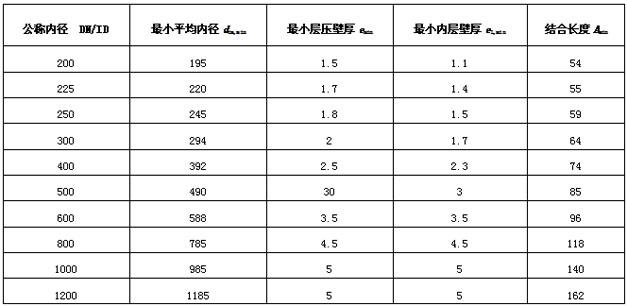

Fourth, product specifications

Dimensions series pipe inner diameter

Implementation of the standards: GB / T19472.1-2004 Unit: mm

Fifth, the connection method

1, before using the pipe installation: should be carefully examined in the course of handling and transportation stack without injury, if found damaged cracks, deformation and other defects pipe, should be promptly removed.

2, manholes and pipe connections: should adopt a flexible packing seal flexible joints, according to the design requirements of the specific structure.

3, trench excavation, foundation should be noted:

(1) clear width trench bottom should be adopted by pipe diameter plus 0.6m;

(2) good drainage trench excavation should be measures to prevent the bottom by water immersion;

(3) must be gravel cushion pipeline infrastructure, the foundation for the general soil thickness of 0.1m; on soft ground, the thickness of not less than 0.2m, according to the design requirements of the specific practices;

(4) the foundation should be compacted, the surface should be smooth. Interface should be set aside part of pipeline infrastructure in order to interface operation groove. Groove length appropriate for the 0.4m-0.6m, depth appropriate for the 0.05m-0.1m, width should be 1.1 times the outer diameter of the pipe.

4, the down tube: When the groove depth is not, by artificial lift tube into the groove, the groove depth is greater than 3m, the available non-metallic pipe rope slipped into the slot. Do hooked ends of the nozzle pipe with a metal rope or self groove side tumbling into the slot.

5, the interface operations:

(1) rubber ring socket mounting location should be between the second and third ripple tank, depending on the number of installed seal design requirements may be, the two seals are separated by a corrugated ring is recommended when using the two;

(2) the interface should be preceded by the jack socket inside and outside surfaces clean, set into the ring in the socket and the socket in a working face and a rubber ring coated with a lubricant (usually with soapy water can be), the insertion direction of the water flow direction, aligned with the centerline of the human or socket set wooden baffles will be installed with a crowbar slowly inserted into the pipe until the bottom of the inner socket;

(3) Upon completion of the interface, the reserve recess immediately filling the same soil compaction;

(4) socket connector pipe should be installed along the flow direction, socket reverse flow direction, and then click Install from downstream to upstream;

(5) should be straight pipe laying, pipe axis of two adjacent corners generally not allowed more than 2 degrees. In order to prevent the pipe axis position when the interface has closed rafts shall adopt measures to stabilize the tube. Bags can be filled with sand inside, after sealing the pressure at the top of the pipe has been rafts, their number varies depending on the size of the diameter. After the pipe interface, you should review the depth and bottom of the tube axis, so that it meets the requirements, such as the emergence of displacement, suspension, pulling mouth phenomenon, should rework.

6, when backfill note:

(1) part of the axillary angle (angle within the range 2d) applied first in the sand, coarse sand infill;

(2) the basis of the site began to pipe above the top of the slot 0.7m range, must be artificial backfill;

(3) can be mechanical tube top over 0.7m from both sides of the pipe axis, while the backfill;

(4) used in various parts of the groove side backfill soil, the best degree of compaction (%) or by design requirements should CECS122: 2001 technical specification requirements.

Shipments of goods priced according to the size of the power meeting, planned product Shandong Foreign customers vehicles (commonly used models) company with inventory, are in stock, money to be arranged within two to three days delivery, Shandong province this invention to customer vehicles, After the factory by 50 km / h control the arrival time; order products (very used models) the company does not have inventory, large production according to customer request, is required to pay 20% deposit, delivery time and circumstances of the production line scheduling, Please call customer service to understand the situation beforehand.

Transportation: Round trip vehicle shipped in large quantities by small quantities go picking station, the specific equipment and freight shipments that require immediate communication and logistics confirmation.

WORKSHOP